rockwell hardness test a in metric or imperial|brinell hardness to rockwell strength : agencies Rockwell Hardness (HR) When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a . Acompanhante EM Vacaria Bibiana Loiraçatop - Acompanha.

{plog:ftitle_list}

Por razões de segurança, por favor clique em Sair e feche o .

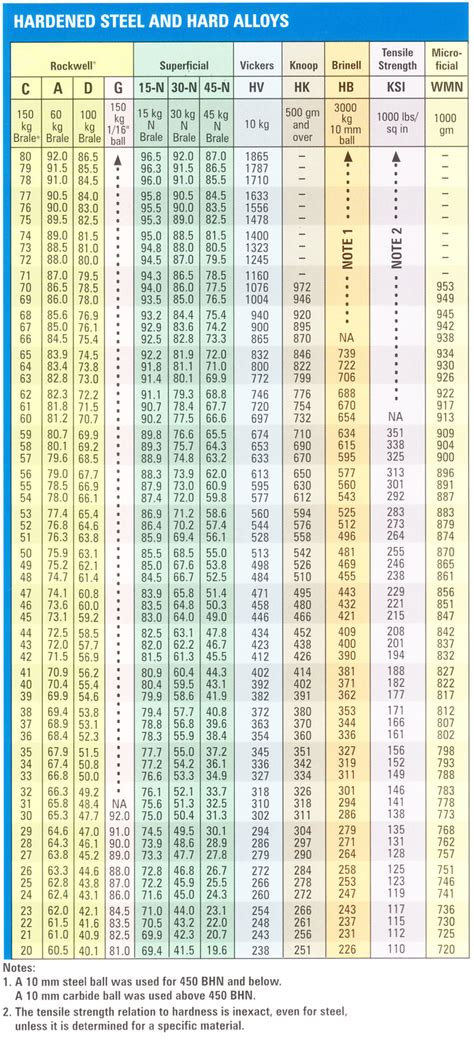

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell and Shore Scleroscope hardnessThe typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball .

The Rockwell hardness test is the most common method for determining . Rockwell Hardness (HR) When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a . It is impossible to define a single conversion method using different hardness test methods. That’s why these standards formulate tables for .Hardness Conversion Chart. Hardness testing measures the resistance of a material to deformation, or hardness, and is an important physical property in manufacturing as it directly correlates to material strength. A variety of .

rockwell hardness conversion chart

The Rockwell hardness conversion calculator is the tool when you are looking to calculate or convert the hardness numbers across various scales. The hardness tests help evaluate a material's resistance to plastic deformation.The Rockwell hardness test is the most common method for determining hardness of ferrous and many nonferrous metals. (See table below.) It differs from Brinell hardness testing in that the hardness is determined by the depth of .Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid. The common test .

Get conversion charts for Rockwell Hardness (B, C) to Superficial Rockwell, Brinell, Vickers and Knoop. Also Length and Area from English to metric.The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. Nationwide . Whether you’re working with Brinell, Vickers, Rockwell, or Tensile Strength measurements, this tool can help you quickly and accurately convert the values to your desired format.Here’s a step-by-step guide on how to use the .Type 316L stainless steel density is 0.289 lb/in3 (8.0 g/cm3); melting point is 1375-1400 °C (2500-2550 °F); 0.2% yield strength is minimum 25 ksi (170 MPa) in annealed and hot finished condition, minimum 45 ksi (310 MPa) in annealed and cold finished condition; Minimum tensile strength is 70 ksi (485 MPa) in annealed and hot finished .

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion. The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

Metric English Comments Cold Head Hot Forge Wire Form Density 7.85 g/cc 0.284 lb/in³ Mechanical Properties Metric English Comments Cold Head Hot Forge Wire Form Hardness, Brinell 302 302 Hardness, Knoop 328 328 Converted from Brinell hardness. Hardness, Rockwell B 99 99 Converted from Brinell hardness. mwcomponents.com 2 Hardness, .

For quenched and tempered steel, the tensile strength (psi) is about 500 times the Brinell hardness number (provided the strength is not over 200,000 psi). Related: Alloy Steel Heat Treating Normalizing, Annealing Temperature Table Chart; Hardness Testing Overview; Vickers Hardness Testing Review; Brinell Hardness Test EquationRockwell Hardness, 73°F Shure Hardness Wear Factor Against Steel, 40 psi, 50 fpm Static Coefficient of Friction . Test Method Units Delrin® 150 0.0513 1.42 0.25 0.9 This information is only to assist and advise you on current technical knowledge and .ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .The Equotip 550 is the most versatile all-in-one solution for portable hardness testing. The Leeb hardness principle is based on the dynamic (rebound) method and is best suited for on-site testing of heavy, large or already installed parts. In combination with the Equotip Portable Rockwell Probe, the Equotip 550 can be 1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).It is very safe in hardening as far as reaching the desired hardness. O1 Tool Steel Properties. The density of 01 steel is 7.85 g/cm3 (0.283 lb/in3); Rockwell C hardness is 50 HRC; Ultimate tensile strength 1690 MPa (245 ksi), Yield strength 1500 MPa (218 ksi), based on oil quenched at 800°C, tempered at 425°C. Chemical Composition

Brinell Hardness Rockwell Hardness Approximate Tensile Strength; A Scale B Scale C Scale; 3000KG 60KG 100KG 150KG Approx. PSI; 400: 72 – 43.1: 202,000: 388: 71.4 – 41.85.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficialRockwell Hardness Testing Machine: Comes in different scales (A, B, C, etc.) to match various hardness levels and types of materials. Indenter: Usually, a diamond cone or hardened steel ball is selected according to the material under examination. Test specimen: the material or component undergoing evaluation. Methodology: Steps: 1.Hardness Rc 36-or equivalent Stress Rupture Stress, ksi - 95a - 100b Life, hr - 23 Elongation, % - 4 AMS 5589 Seamless Tubingg Property Room Temperature 1300°F Tensile Strength, ksi 185 - Yield Strength 150 - (0.2% Offset), ksi Elongation in 2 ln.,% 12 - Hardness Rc 36-or equivalent Stress Rupture Stress, ksi - 72.5 Life, hr - 23 Elongation, % - 5

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness TestingRockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. With a carbide ball, the specified reference depth is .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured. The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. .

rockwell hardness chart

Hardness of Titanium Grade 2. Rockwell hardness of commercially Pure Titanium – Grade 2 is approximately 150 HRB. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Menu. Home; Products; Metric Fasteners. Hex Head Fasteners. DIN 931 / ISO 4014 Partially Threaded Hex Cap Screw. 8.8 Grade Bare Steel / Zinc Plated; 8.8 Grade Hot Dip Galvanized (ISO FIT)

Calculate the height of a cube made of Bronze, which weighs one metric ton. . Rockwell hardness of copper beryllium – UNS C17200 is approximately 82 HRB. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .

That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; . Rockwell C Hardness Range

rockwell c to b hardness

rockwell c hardness range

Loop Tack Tester sourcing

File formats sometimes use the same or similar file extension letters, and it can be confusing. You might thinkyou have a WMA file, but it could be something that just looks like it has that file extension. For example, WMF . Ver mais

rockwell hardness test a in metric or imperial|brinell hardness to rockwell strength